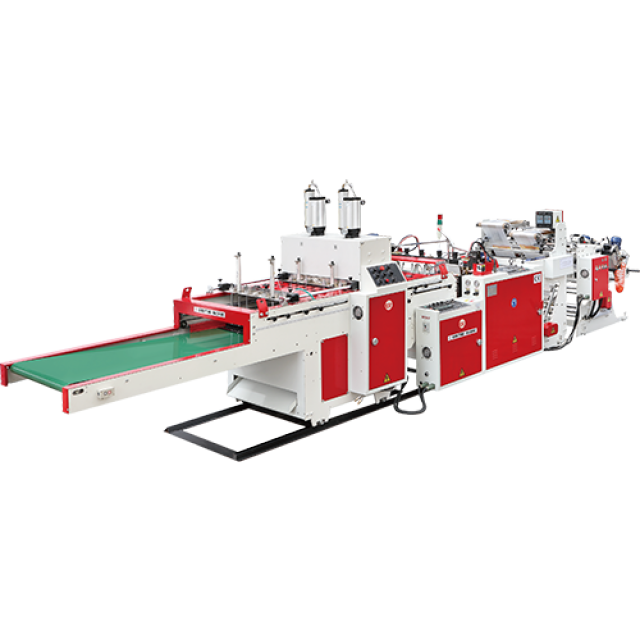

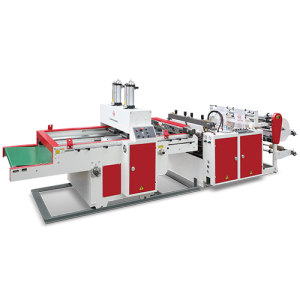

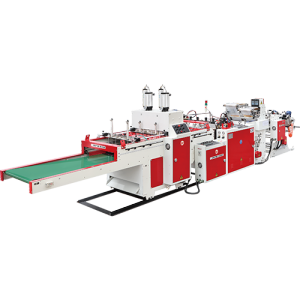

It is applied to produce the printed double-lane or non-printed vest bags/ T shirt bags, using HDPE, LDPE roll film. It adopts PLC control, double servo motors control and the touch screen actual display to finish the feeding, sealing, cutting, punching in one process,which can save man-power greatly and yield good economic result.

Unwinder

1 Unwinder adopts air cylinder automatic load design, max diameter of the unwinder is 700mm

2 Adopts AC frequency motor driving constant tension control, feeding speed is according to the producing speed

3 Unwinding shaft adopts heavy-chain air shaft

4 Unwinder part has the EPC and automatic tension control

5 Automatic stop design when rolls film finish or damage

Automatic EPC control

1 This device special for this high speed model

2 When roll film feeding so fast that the film will move little left and right, with this EPC device to be control the film feeding corrected to the right position

3 This EPC system will enhance the productivity of machine

4 One set EPC system to control two lines

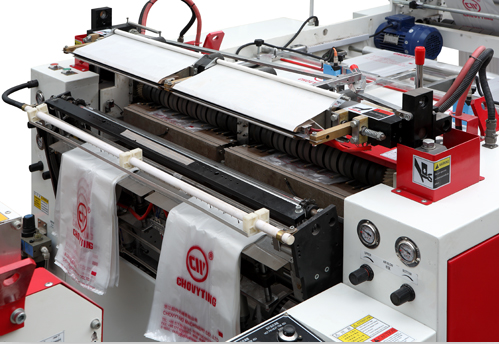

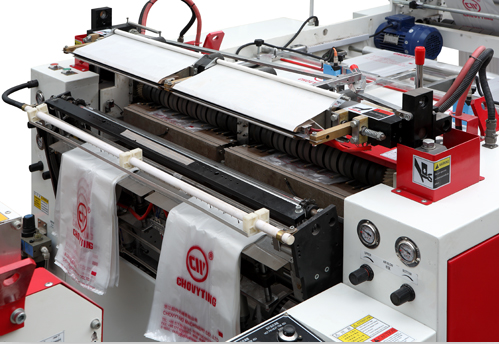

Sealing and cutting knife device

1 Sealing knife with 90 degree “turnover” device ,which easy to clean the knife, which is better to keep the maintenance easily

2 The whole set of bags has design of swaying, no paste between two bags mouth (ITALY DESIGN)

3 Fully automatic tacking of whole set and levelling stack design

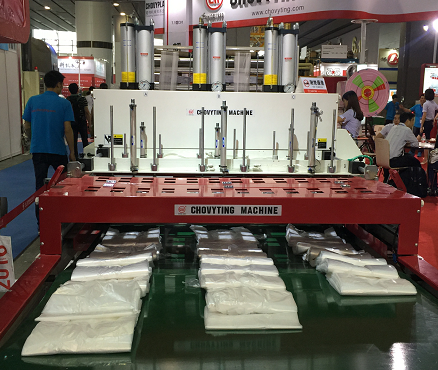

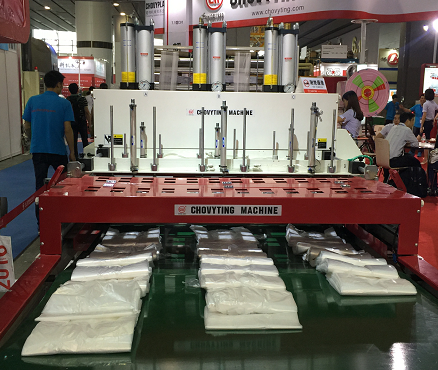

Hydraulic air cylinder punch (photo have 3 punch as reference CW-400V2 only two punch)

1 With 5 tons hydraulic air cylinder punch from Taiwan

2 The motor of clip for clamp the bag is Ac inverter motor control 1.5KW

3 Automatic collect bags and finish stack bags with double fold device