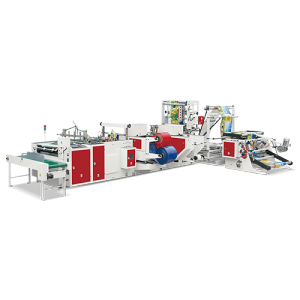

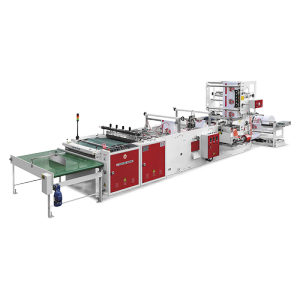

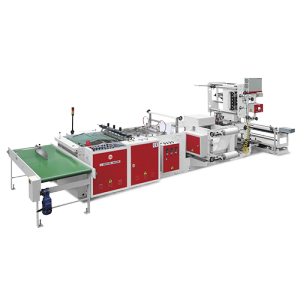

1 With soft loop handle bag function

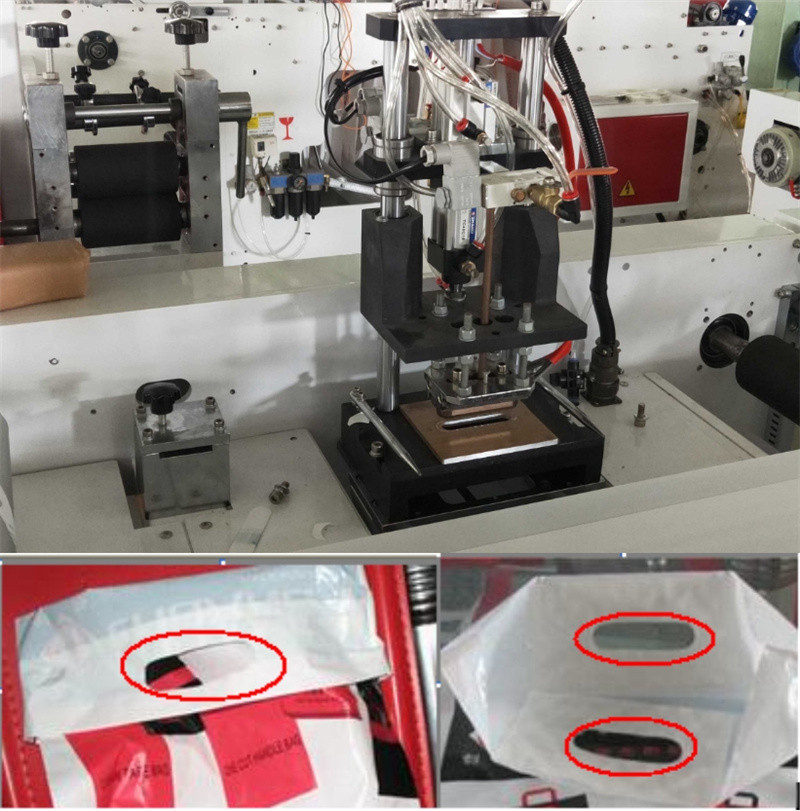

2 With patch handle bag function

3 With poly draw handle bag function

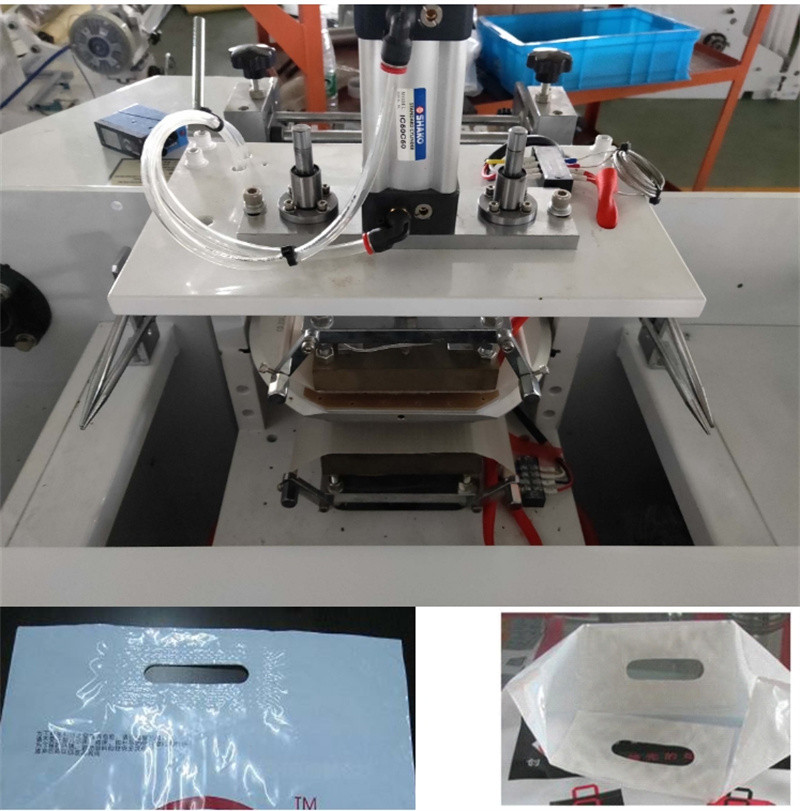

4 With die cut handle bag function

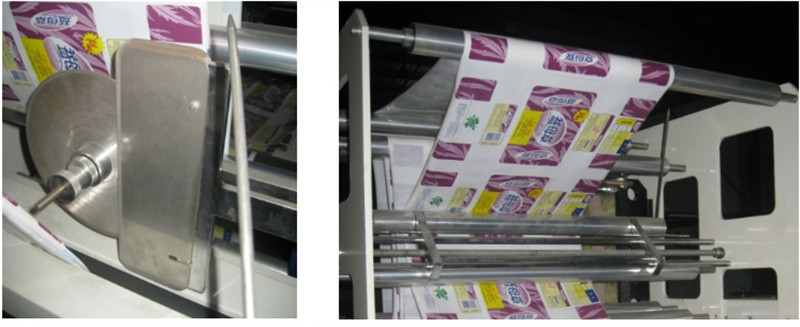

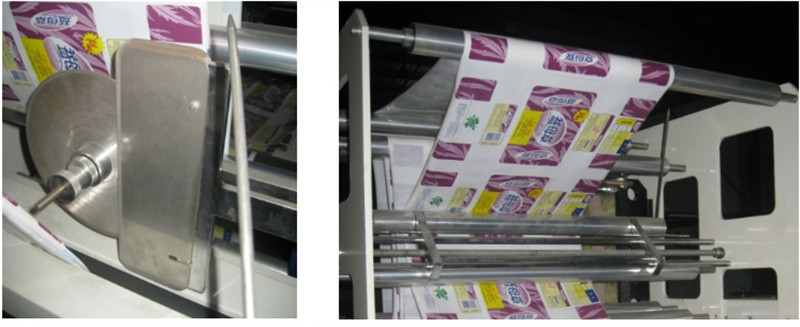

Common unwinding

1 Unwinding adopt common loading , max diameter of raw rolling material is φ600mm

2 Adopt magnetic powder tension control. Manual adjust the tension

3 Unwinding shaft is heavy-chain plug axle

4 Unwinding with EPC

5 Triangle folding device as optional device(extra1000usd)

Top-folding continuously sealing device

1 Top-folding continuously sealing, the width size of bag not be limited

2 Inside heating wire sealing, which is suitable for full colors of bag

3 Adopt import heat wire, steady warming, hard sealing

4 Double adhesive tape device for side sealing bag

Top folding and round bottom gusset device

1 14mm high hardness steel plate top folding and round bottom gusset

2 Special guide plate and roller ,which offer less friction fold

3 With flat press roller

4 More thin round disc bottom gusset

5 U style mould bottom molding

Soft loop handle bag device

1 Double layer unwinder

2 The whole type steel plate base, and special support bag structure

3 High quality oval sealing knife from up and down

4 Hydraulic skew angle feeding soft loop

5 90 degree turnabout gear rotary soft loop

6 Special oblique drag style rotary soft loop

7 Micro-motor driver soft loop handle go forward and back off

8 Centralize style air control system

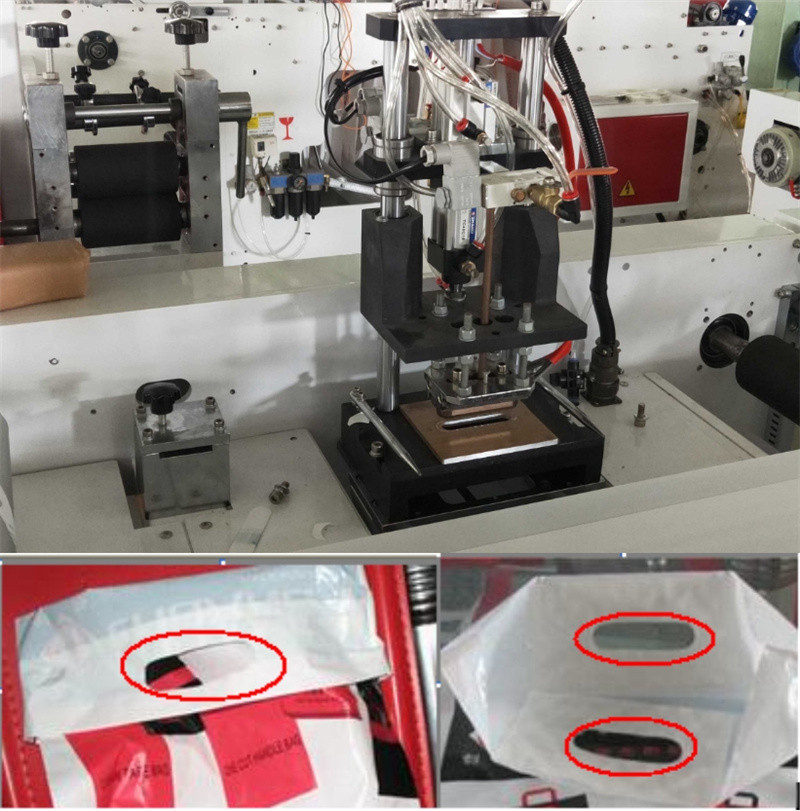

Patch handle bag device

1 Pneumatic control feeding

2 Turnabout cylinder control patch

3 With flying knife cutting fast

4 Special pattern sealing mould

5 Micro-motor driver patch go forward and back off

6 Base mould of patch device adopt whole steel plate

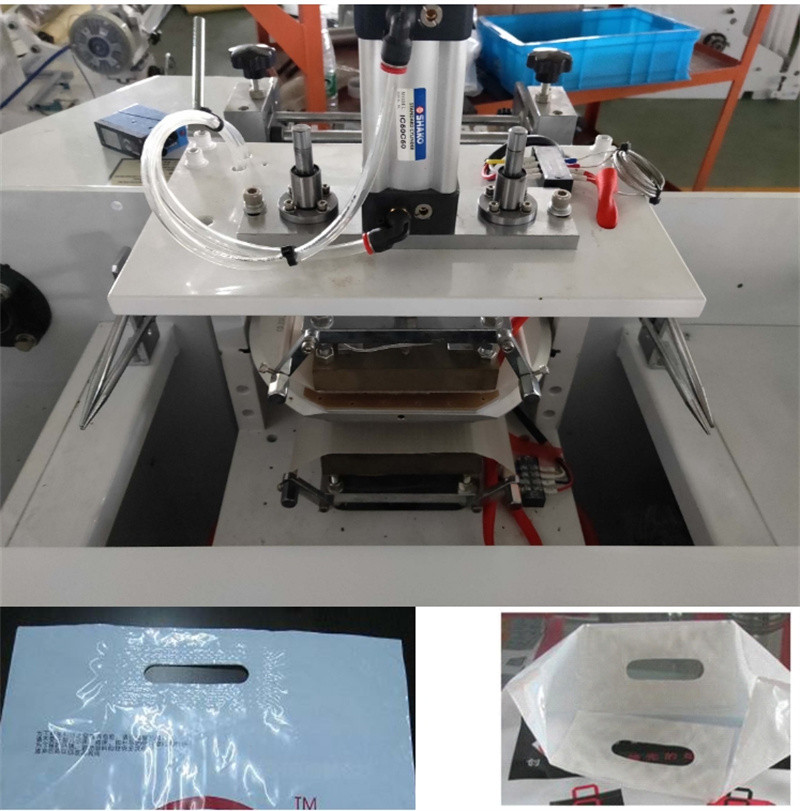

Heat sealing handle punch

1 High hardness gear steel smooth pillar

2 Air outside waster film blower hopper

3 The whole style rotary 180 degree

4 High hardness alloy aluminium puncher base plate

5 Hot handle puncher 20X90m

6 Stroke of puncher: 25mm X 2

7 Temperature of puncher 0-300 degree

Poly draw handle bag device

1 Unwinder with double disc plate

2 Non-tension unwind

3 With 25mm half hole puncher

4 With poly draw tape unwind

5 With top fold sealing bar

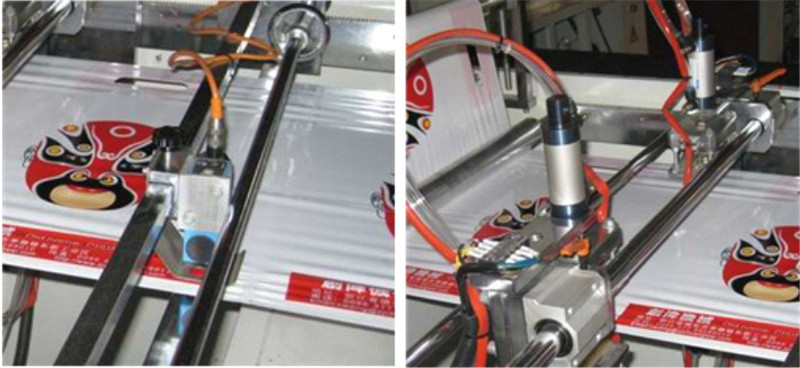

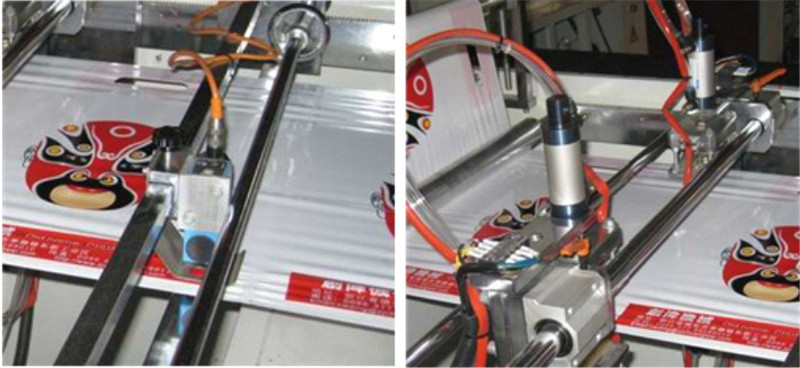

Photocell of printing and preheating

1 Printing image tracking adopts photocell from SICK FROM GERMANY

2 The photocell of priting together with high technical computer

3 The pre-sealing knife is designed specially of bottom four layers film, high speed produce bag

4 Double sides heating, double cylinder driven, strong for gusing, and strong for sealing

Side sealing parts

1 Side sealing knife principal axis transmission belt cylinder lifting and down

2 Side sealing knife with water cycle cooling system

3 Side sealing knife adopt best of breed material, high temperature heating ametabolic

4 Side sealing knife with concealed style heating tube, temperature steady

5 Turnover heavy side sealing knife, humanism structure design, turn fast, easy to cleaning

Convey collect device

1 Collect table adopt automatic collecting bag feeding (intermission model and continuum model)

2 When the bag reach to a certainty quantity, collect table will move automatically, and continuo producing.

3 Collect table is driven by Micro-motor reducing servo